Clients' Working Site

Advantage

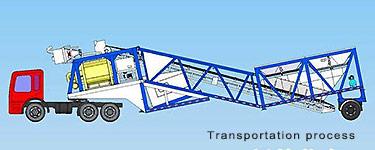

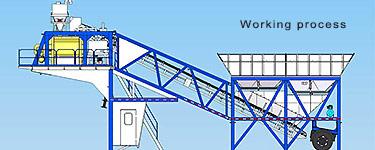

1. Adopting module structure, designed as per the loading of container standard. All modules are in one trailing unit. Easy for installation and disassembly. Fast for moving.

2. Main mixing unit is JS1000 double-shaft, forced concrete mixing mixer, with good mixing quality, high production efficiency. Perfect mixing can be done within ideal time period for dry-hard, half-dry-hard, plastic and concrete with any mixing ratio.

3. All scaling elements and control elements of scaling unit are imported elements and controlled by computer, guaranteeing completely accurate scale and stable function.

4. Platform or ladder is equipped to each part needing maintenance and repairing. Good for maintenance.

5. The whole system adopts complete automatic system via computer, with dynamic panel display, to show clearly of the running of each part. Visualized monitor interface provides clear and accurate observing to the site working procedure. Table or list can be print out.

6. Electrical control system adopts import elements, providing a stable and powerful function. Automatic test for the abnormal working condition, Word, sound, light alarm, easy and good for the maintenance and trouble shooting.

Specification

| YHZS60 Mobile Concrete Mixing Plant Main Specification | |

| Model | YHZS60 |

| Theoretical capacity | 60m3/h |

| Mixing unit | JS1000 |

| Max. aggregate size | 80mm |

| Size of aggregate silo | 2×11m3 |

| Weighing and conveying of aggregate | Weighingd and lifted by belt |

| Weighing of aggregate | 3000Kg ±2% |

| Weighing of cement | 720Kg ±1% |

| Weighing of water | 360Kg ±1% |

| Weighing of additive agent | 36Kg ±1% |

| Power of whole unit | 85Kw |

| Quality of whole unit | 24T |

| Transport way | Semi-trailer |

|

Outline (working statue: length×width×height) |

17.7m×3.6m×8.2m |

|

Outline (transport statue: length×width×height) |

18.3m×2.4m×4.35m |

| Discharging height | 3.8 m |

| Powder silo (option) | Depends on the customer. Quantity and capacity are flexible. |

| Cement screw (option) | A φ219 screw is equipped to each powder silo |

Tags: kushlan electric cement mixer concrete mixing plant manufacturers rmc plant manufacturers cheapest concrete mixer cement mixers electric crawler crushing plant Crawler Excavators macons self loading concrete mixer floor placing boom boom concrete pump for sale in Mogadishu concrete pump truck rates

Products

Concrete Mixers

Concrete Batching Plant

Concrete Conveying Plant

- Pompa Beton Seri HBT/DHBT

- Pompa Beton Boom yang Dipasang di Truk

- Pompa Beton Montase Truk

- Boom Penempatan Beton Hidrolik Menaik Sendiri untuk Shaft Lift

- Boom Penempatan Beton Hidrolik Mobile

- Boom Penempatan Beton Hidrolik Menaik untuk Lantai

- Mixer Transit Beton di Truk

- Pompa Beton XBS/DXBS Fine Stone

- Truk Mixer Beton

- Mixer Truk Beton 6cbm

Related Concrete Equipment

Concrete Block Making Plant

NEWS

- Pabrik batching beton HAMAC HZS180 berhasil dipasang di Filipina

- Pabrik batching HZS120 RMC telah dikirim ke Filipina

- Pabrik pembuatan tiang beton telah dikirim ke Filipina

- Mixer Beton Memuat Sendiri HMC400 Dikirim ke Meksiko

- Pabrik pembuat tiang beton telah dikirim ke Filipina

- Mesin Pembuat Blok Beton QT4-15 Dikirim ke Peru

- Berapa ukuran blok beton berlubang di Filipina

Dapatkan Kutipan

Dapatkan Kutipan Obrolan Online

Obrolan Online